The 2021 Nobel Prize in physics was awarded to Syukuro Manabe, a Japanese-born American citizen. This was in recognition of his research that clarified the impact of atmospheric carbon dioxide concentrations on the climate. On the basis of his research, global warming countermeasures have been promoted on a global scale under agreements such as the Kyoto Protocol and the Paris Agreement.

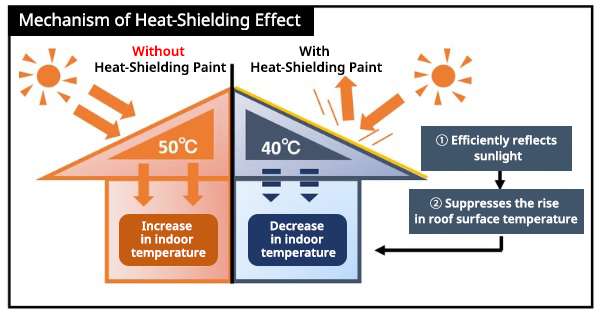

Reducing CO2 emissions is a major theme, and one way to contribute to this is through the use of heat-shielding paint. By reflecting heat instead of absorbing it, this paint helps prevent increases in nighttime atmospheric temperatures. This paint is also expected to reduce electricity consumption by air conditioners and other electrical devices, and work is underway to impart such properties to many of the paints being used for buildings and automobiles.

Now then, how are the heat-shielding properties of paint verified?

The answer is that the paint (applied to iron plates or concrete, depending on the application) is exposed to natural sunlight outdoors and the temperature increase is measured to verify the degree of heat absorption and heat reflection when exposed to natural sunlight.

However, sunlight is greatly affected by the season, time, and weather, so this method does not allow for stable evaluations.

In tests such as performance evaluations of heat-shielding paints using natural sunlight, establishing a stable test environment is a serious issue.

Of course, outdoor testing is necessary, but unless tests are consistently conducted under the same conditions, accurate comparisons with other companies’ products, conventional products, and before-and-after comparisons cannot be made. Also, since the sun moves over time, you need to adjust the angle at which the paint surface is exposed to sunlight at short intervals.

Factors contributing to changes in conditions include:

・Changes in irradiation intensity (The irradiation intensity differs between morning/evening and daytime.)

・Changes in the angle of irradiation (Since the sun moves, the angle at which light hits the irradiated object changes.)

・Changes in optical conditions due to weather (Even if it is sunny all day, if clouds cover the sun, the irradiation intensity will decrease.)

・Changes in ambient temperature (Naturally, the outside air temperature differs between summer and winter. When the outside temperature is low, the heat accumulated in the paint or substrate is efficiently released.)

・Changes in wind (Heat dissipation improves when there is wind, and decreases when there is no wind.)

The above are a few examples.

The XG-500EFSS super spotlight lighting type artificial solar light can stably irradiate an area with a diameter of 10 cm at 1 kW/m², equivalent to direct sunlight. In addition, it irradiates with high precision as the variation in irradiance in the area is within ±5%.

XELIOS artificial solar lighting exhibits almost no change in its optical characteristics, allowing tests to be conducted under the same optical conditions over a long period. This is because one of the features of the XELIOS artificial solar lighting is that it exhibits almost no change over time.

In addition, conducting tests in a temperature-controlled room allows you to eliminate environmental factors such as changes in ambient temperature and wind.

XELIOS artificial solar lighting provides our customers with a stable optical testing environment. Data measured in a stable testing environment is extremely important for your sales promotion and branding. Please use XELIOS artificial solar lighting to conduct tests that will help improve your profits.

Please refer to the page below for specifications and performance.

If you would like to evaluate the performance of heat-shielding paint in a stable environment, please consult SERIC, which has extensive experience.