Many people become concerned about sunburn in the summer. However, we are not talking about human sunburn this time. We are talking about the effects of ultraviolet rays on materials and the chemical changes that occur when they are exposed to sunlight.

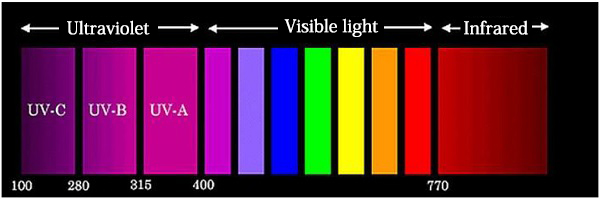

Generally, xenon lamps are most commonly used as the light source in ultraviolet degradation tests. The light emitted from xenon lamps includes UV-A (315–400 nm), UV-B (280–315 nm), and UV-C (wavelengths below 280 nm). By irradiating with raw light from a xenon lamp, deterioration occurs more quickly than with outdoor exposure (a method of actually exposing samples outdoors to check for changes in condition), so it is effective in cases where rapid results from ultraviolet degradation tests are required.

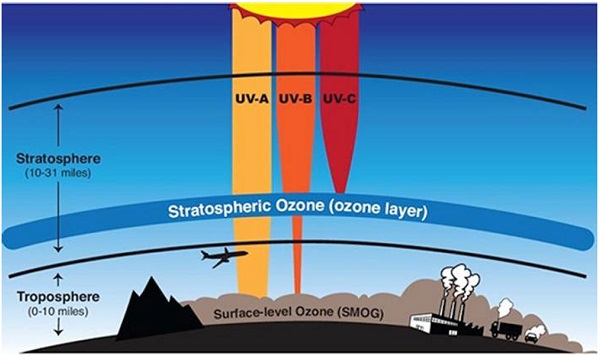

There is a layer in the atmosphere called the ozone layer. This ozone layer blocks UV-C and a portion of UV-B (280–300 nm), so only ultraviolet rays in the 300–380 nm range reach the Earth’s surface.

Some UV-B (ultraviolet rays with wavelengths shorter than 300 nm) and UV-C are blocked by the ozone layer and do not reach the Earth’s surface. However, because UV rays in this range accelerate the degradation of materials, irradiating with UV rays in this range is very effective for accelerated degradation testing. The raw light from a xenon lamp contains ultraviolet rays in this range, so xenon lamps can be considered optimal for accelerated degradation testing.

But what about as an alternative to outdoor exposure testing?

Ultraviolet irradiation that does not exist in the natural environment on Earth should not be consistent with outdoor exposure tests.

If the correlation between the accelerated degradation test and the outdoor exposure test has already been established, there is no problem. However, if not, isn’t an outdoor exposure test still necessary? In addition, there are accelerated degradation testing devices that irradiate with both ultraviolet and infrared rays. In the case of tests using these devices, it can be difficult to determine whether the degradation is caused by ultraviolet rays or by infrared rays (heat).

Moreover, in the case of photoreaction tests using natural sunlight, such as with photocatalysts, the light source equipment for accelerated degradation testing cannot produce the correct reaction. This is why it is essential for outdoor exposure testing to use a light source that approximates the spectral characteristics of natural sunlight.

When I was young (before joining Seric), I thought that sunburn was caused by the heat of the sun. Of course, my understanding was mistaken, and now I know that the cause of sunburn is ultraviolet rays. I believe this is common knowledge for everyone.

Having said that, I think it is mistaken to assume that only ultraviolet rays need to be irradiated in various exposure tests. In fact, among customers who request light source devices that can simulate outdoor exposure, many wish to irradiate target objects with not just ultraviolet rays but also heat.

In other words, there are cases where the irradiation light emitted by exposure test equipment needs to cover a wide range of wavelengths from ultraviolet to infrared.

In addition to the destruction of molecular structures by ultraviolet rays, expansion caused by heat can also contribute to degradation. As such, the demand for light source devices capable of irradiating both ultraviolet and infrared rays is increasing.

There are two models of SERIC light source devices that can achieve this.

☆Ultraviolet + visible light + infrared irradiation

→ XELIOS artificial solar lighting XG-500LFSS *Irradiation range: φ100 mm

☆Large area + ultraviolet + visible light + infrared + long-duration irradiation

→ Lightfastness test device SML-2K Series *Irradiation range: □300 mm

It is said that irradiating with light equivalent to AM1.5 for 4 hours corresponds to the average daily amount of solar radiation over the course of a year.

In other words, both models introduced here can irradiate light equivalent to direct sunlight (AM1.5), and customers can select the model based on the size of the area that can be irradiated.

Please refer to the page below for specifications and performance.

If you are considering conducting lightfastness tests, accelerated degradation tests, or photoreaction tests under lighting conditions that are extremely close to those of the outdoor environment, please consider SERIC’s artificial solar lighting and lightfastness test devices, which have their spectral characteristics disclosed. We will propose a device that meets your requirements and budget.

Please feel free to contact us.